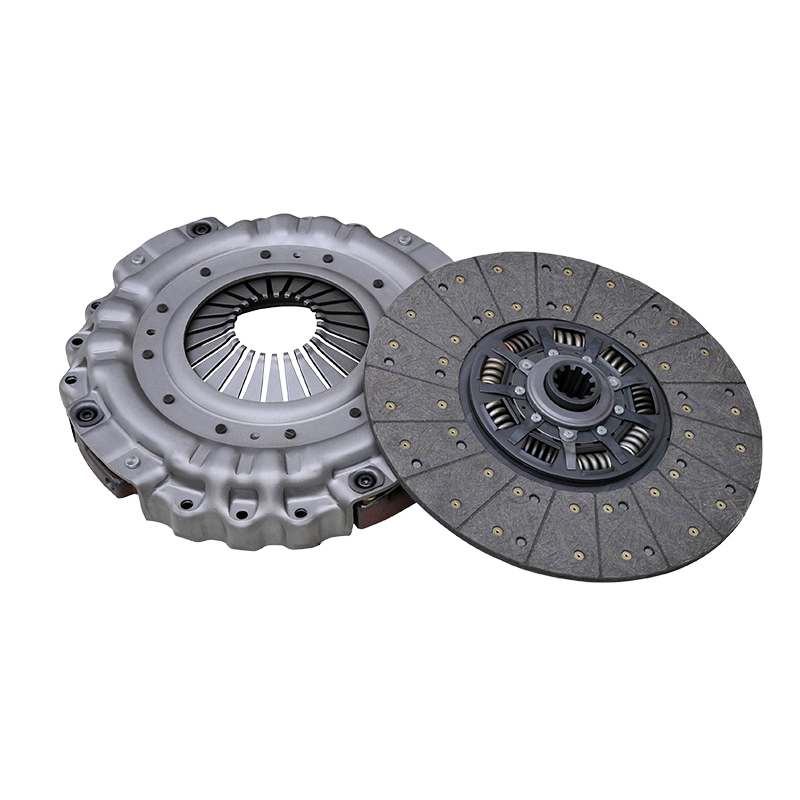

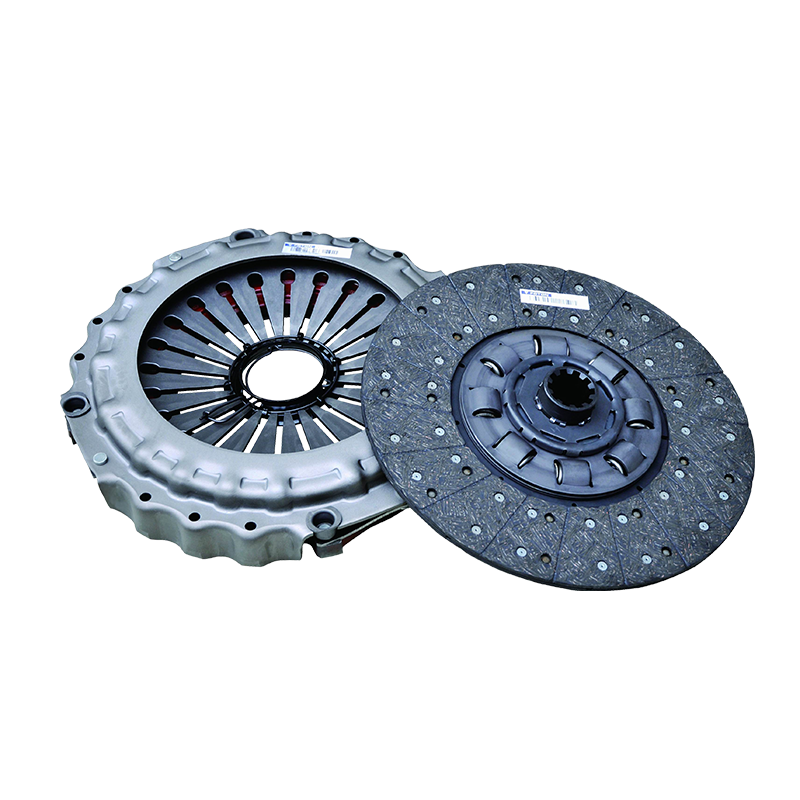

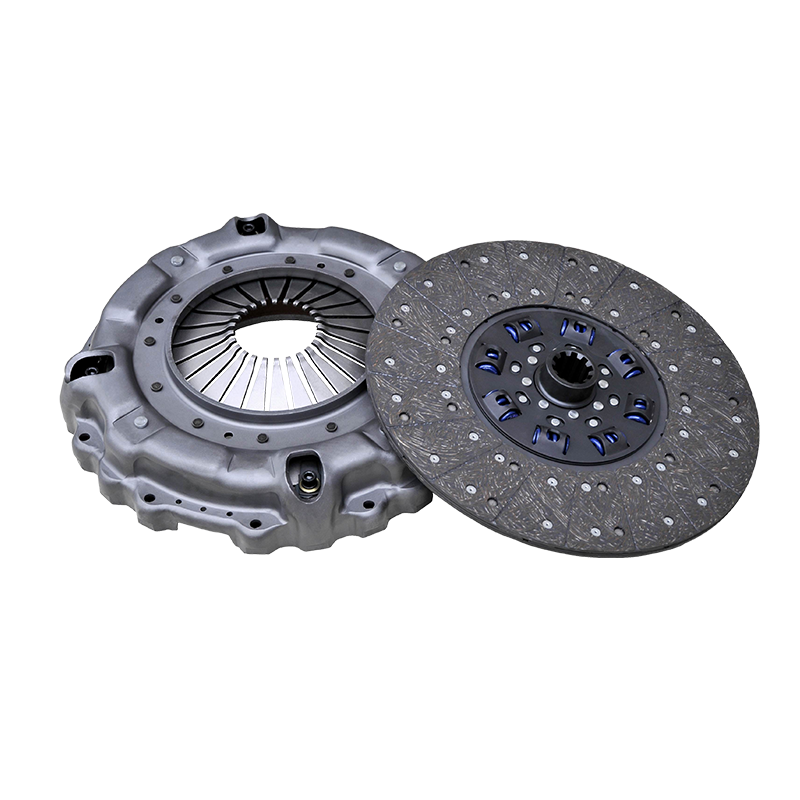

In the heavy-duty truck market, improving the durability of clutch components is one of the key factors in improving overall vehicle performance and reducing maintenance costs. Suzhou Ossder Clutch Co., Ltd., as a well-known brand of heavy-duty vehicle and bus clutches in China, supports many well-known automobile manufacturers such as Shaanxi Automobile, Jiefang and Dongfeng, and is committed to the design, R&D, manufacturing and sales of high-quality clutch products , strictly follow German technical standards. This provides a strong guarantee for improving the durability of the clutch assembly. Next, we will discuss how to improve 430 push clutch assembly durability by combining several aspects of technology, materials and processes.

1. Material selection and heat treatment

Suzhou Ossder Clutch Co., Ltd. strictly controls the raw material procurement and heat treatment process of clutches. Choosing high-strength, high-temperature-resistant, and wear-resistant materials is the basis for improving durability. The use of high-quality alloy steel and composite materials can significantly improve the clutch's fatigue resistance and thermal crack resistance. In addition, the precise heat treatment process ensures that the key components of the clutch such as the friction plate, pressure plate and flywheel have better hardness and toughness, thereby maintaining stable performance during long-term high-load operation.

2. Precision manufacturing and mold management

The durability of a clutch is closely related to the precision with which it is manufactured. Suzhou Ossder Clutch Co., Ltd.'s meticulous management of the mold manufacturing and production processes can ensure the dimensional accuracy and surface finish of the clutch components. This not only reduces assembly errors, but also reduces wear on friction plates and other components during use. Through precision machining, the clutch allows for smoother power transfer, reducing the chance of premature failure.

3. German technical standards and quality control

Suzhou Ossder Clutch is produced in strict accordance with German technical standards, which means that throughout the entire manufacturing process, every link is closely monitored to ensure that the product meets high performance and high durability requirements. From design to manufacturing, quality control runs throughout. Through strict quality inspection procedures, clutch products can undergo multiple stringent tests before leaving the factory, such as torque tests, durability tests and heat treatment tests, to ensure that each product can perform well under harsh working conditions.

4. Innovation of friction materials

Friction plates are the key to improving clutch durability. Suzhou Ossder Clutch continues to innovate friction materials and selects high wear-resistant and high heat-resistant composite materials to improve the friction performance of the clutch. This type of material can not only improve the wear resistance of the clutch, but also enhance its heat dissipation ability to avoid overheating problems caused by long-term work. In addition, optimized friction materials can also reduce the stick-slip phenomenon between the friction plate and flywheel and extend the service life.

5. Surface treatment process

The surface treatment process of the clutch also has an important impact on its durability. Suzhou Ossder Clutch uses advanced surface treatment technologies, such as chrome plating, zinc plating, etc., to improve the anti-corrosion and oxidation resistance of components. This not only extends the service life of the clutch, but also reduces the failure rate of vehicles in high humidity or harsh environments.

6. Continuous R&D and technological improvement

Suzhou Ossder Clutch focuses on R&D and innovation, and continuously makes technological improvements based on customer needs and market feedback. Through the structural optimization design of the clutch assembly and mechanical analysis under high-load conditions, the company can further improve the durability of the product. For example, by improving the elasticity and damping characteristics of the clutch disc, wear over time can be reduced.

7. In-depth cooperation with automobile manufacturers

Suzhou Ossder Clutch has cooperated with many well-known automobile manufacturers such as Shaanxi Automobile, Jiefang and Dongfeng to gain an in-depth understanding of the use needs of heavy-duty trucks under different working conditions. Through this close cooperation, Ossder can customize the production of more durable and efficient clutch components according to the power transmission requirements of different models, thereby increasing the actual service life of the product.

English

English русский

русский

English

English  No.25, Hu Chuang Road, New District Industrial Park, Suzhou, Jiangsu, China.

No.25, Hu Chuang Road, New District Industrial Park, Suzhou, Jiangsu, China.  +86-13338663262

+86-13338663262