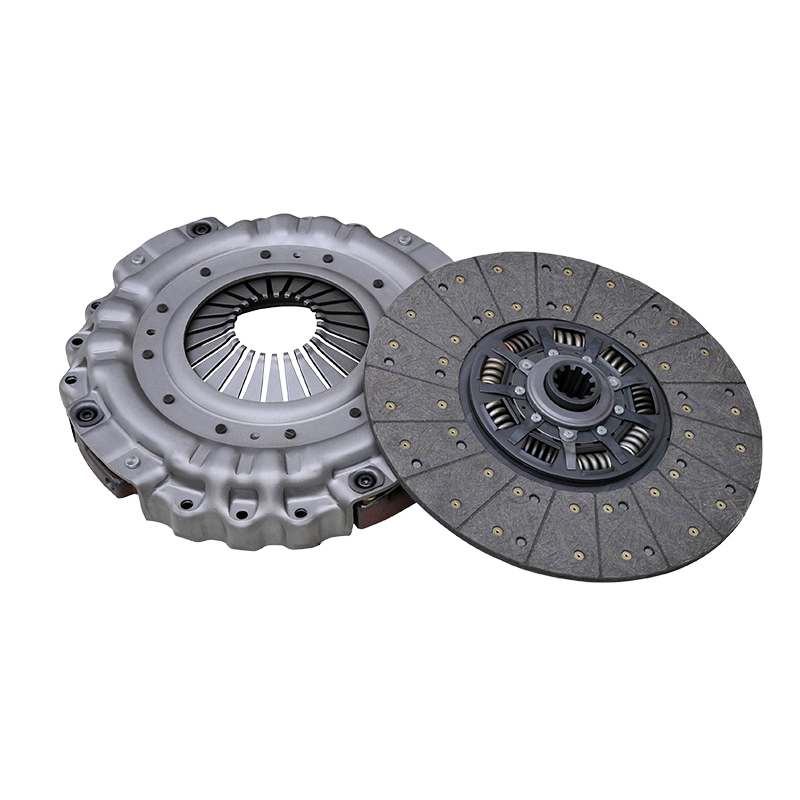

The core competitiveness of the release bearing of the 380 clutch assembly lies in its precise design and manufacturing. This precision is reflected in every detail of the bearing. From material selection to manufacturing process, to final assembly and commissioning, every link has been strictly controlled and optimized.

Application of material science: The material selection of the release bearing is crucial. The 380 clutch assembly uses a special alloy steel with high strength and high hardness as the base material of the bearing. This material is not only highly wear-resistant, but also can withstand extremely high loads and speeds, ensuring that the bearing maintains stable performance during long-term use. At the same time, advanced coating technology is also used on the surface of the bearing to further improve its wear resistance and corrosion resistance.

Innovation in manufacturing technology: In terms of manufacturing technology, the 380 clutch assembly uses precision machining and heat treatment technology to ensure the dimensional accuracy and geometric shape accuracy of the bearing. This high precision not only reduces the friction and wear between the bearing and other components of the clutch, but also improves the overall performance and stability of the clutch. In addition, the innovation of manufacturing process also includes the optimization of the internal structure of the bearing, such as the shape, number and arrangement of rolling elements, which further improves the bearing's load capacity and service life.

Precision of assembly and commissioning: During the assembly and commissioning stage, the 380 clutch assembly uses advanced automation equipment and precision testing instruments to ensure the precise fit between the bearing and other parts of the clutch. This precise fit not only improves the response speed and accuracy of the clutch, but also reduces failures and wear caused by assembly errors.

The most direct benefit of the precision-designed release bearing is reduced wear. During the operation of the clutch, the release bearing needs to withstand extremely high loads and speeds, while also generating friction with the clutch pressure plate and friction plate. If the bearing design is not precise enough, it will lead to increased wear, which will affect the performance and life of the clutch. The release bearing of the 380 clutch assembly can effectively reduce this wear due to its precision design and manufacturing. This not only extends the service life of the bearing, but also reduces the maintenance and replacement costs of the clutch.

In addition to reducing wear, the precision-designed release bearing can also improve the response speed and shifting accuracy of the clutch. During the shifting process, the release bearing needs to respond quickly to the driver's operation to separate or engage the clutch pressure plate from the friction plate. If the bearing's response speed is not fast enough or the accuracy is not high enough, it will cause uneven shifting or impact. The release bearing of the 380 clutch assembly, due to its precise design and manufacturing, can ensure that this operation is completed in a very short time, thereby improving the clutch's response speed and shifting accuracy. This not only improves the driving experience, but also reduces vehicle failures and safety hazards caused by uneven shifting.

The benefits of reduced wear, improved response speed and shifting accuracy brought by the precision-designed release bearing work together on the 380 clutch assembly to make its shifting smoother. During driving, the driver can feel that the clutch engages and disengages more smoothly and quickly, and the impact and frustration during shifting are greatly reduced. This smooth shifting experience not only improves driving comfort, but also enhances the driver's control and confidence in the vehicle.

English

English русский

русский

English

English  No.25, Hu Chuang Road, New District Industrial Park, Suzhou, Jiangsu, China.

No.25, Hu Chuang Road, New District Industrial Park, Suzhou, Jiangsu, China.  +86-13338663262

+86-13338663262  zh@ossder.com

zh@ossder.com