The key reason why the 430 pull-type clutch assembly can occupy a place in heavy-duty trucks lies in its advanced pull-type diaphragm spring structure. This innovative design not only significantly improves the stiffness and stability of the clutch, but also optimizes the overall performance of the clutch, making it better able to adapt to the complex and changing working conditions of heavy trucks.

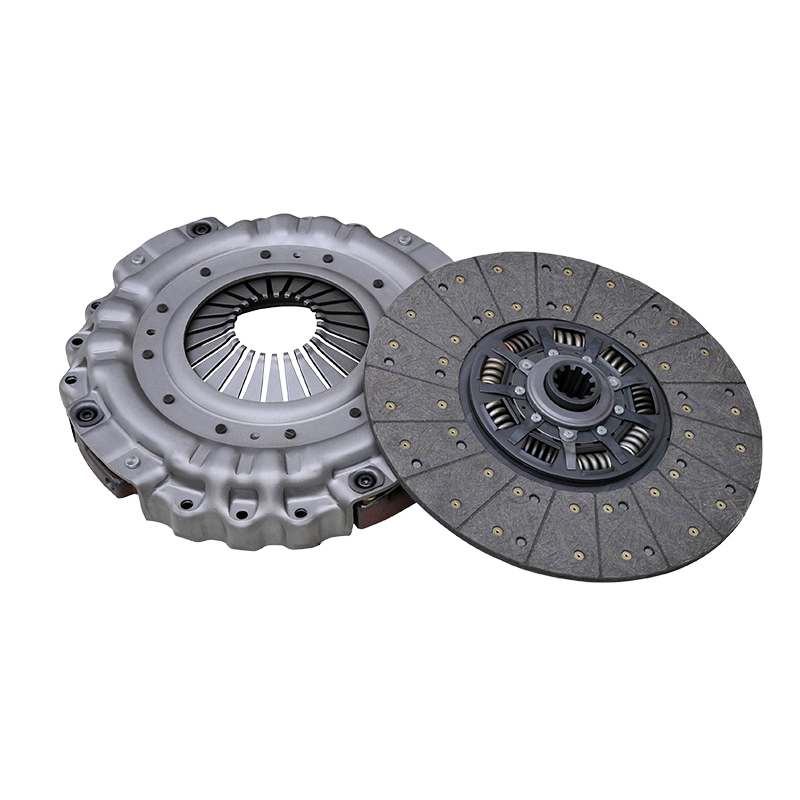

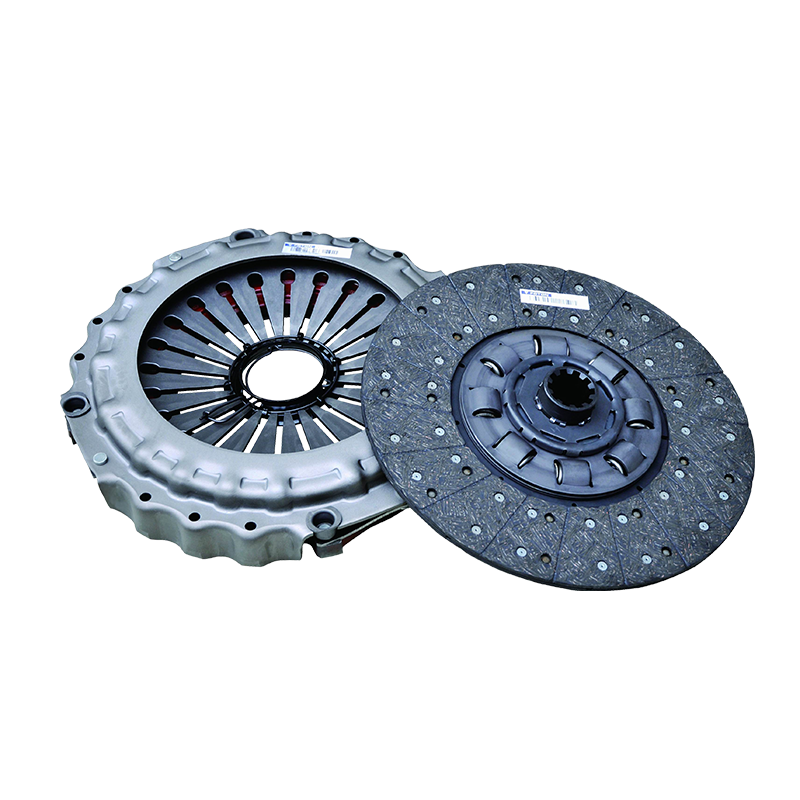

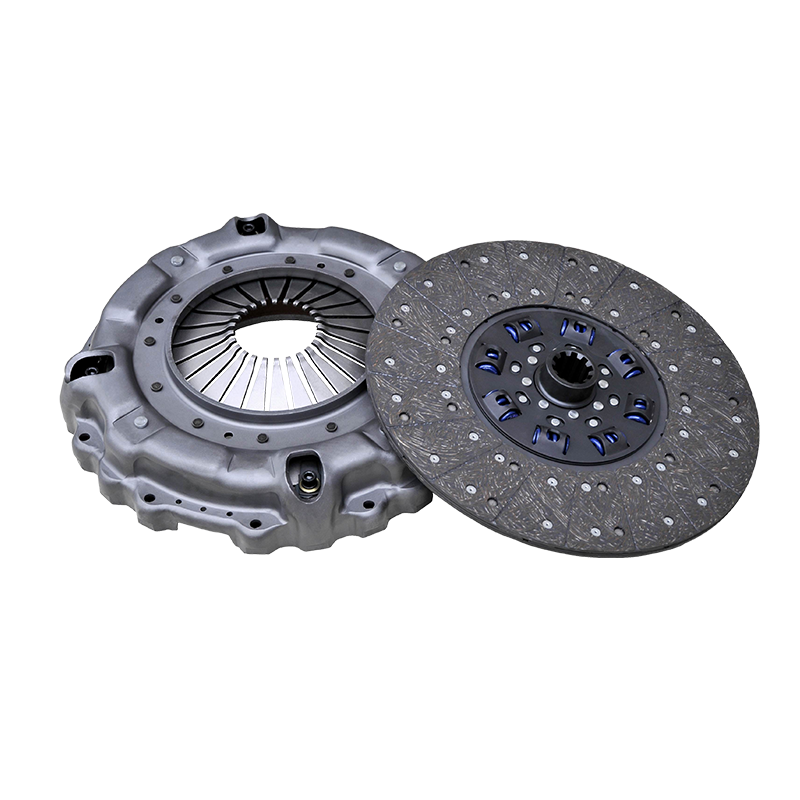

Traditional push clutches usually rely on coil springs or disc springs to provide pressing force. This structure is prone to insufficient pressing force due to spring fatigue or deformation during long-term use, thereby affecting clutch performance. The 430 pull-type clutch uses a diaphragm spring structure. This spring is stamped from a thin steel plate and has high strength, high stiffness and good elastic recovery ability. The diaphragm spring can produce evenly distributed pressure when it is stressed, ensuring that the clutch can transmit power smoothly when engaged, while reducing wear and noise.

The pull-type diaphragm spring structure also makes the clutch separation more complete. During the separation process, the deformation of the diaphragm spring can generate greater separation force, thereby ensuring complete separation between the clutch plate and the flywheel, avoiding power interference and frustration when shifting gears. This design not only improves the smoothness of shifting, but also extends the service life of the clutch plate.

In addition to the unique pull diaphragm spring structure, the 430 pull clutch assembly further improves its performance through a series of optimized designs.

Lightweight design: In heavy-duty trucks, lightweight design is of great significance for improving fuel economy and reducing emissions. The 430 pull-type clutch assembly achieves overall weight reduction by using high-strength, lightweight materials and optimizing the structure and size of components. This not only reduces the clutch's moment of inertia and improves transmission efficiency, but also reduces vehicle fuel consumption and emissions.

Application of wear-resistant materials: The clutch plate is one of the most important wear parts in the clutch assembly. The 430 pull clutch assembly uses high-performance wear-resistant materials, such as ceramic fiber, aramid fiber, etc. These materials have excellent wear resistance, heat resistance and fatigue resistance. By applying these materials to the friction surfaces of the clutch plates, the service life and durability of the clutch can be significantly increased.

Optimized heat dissipation design: In heavy-duty trucks, clutch components generate a large amount of heat under long-term high-load operation. If the heat cannot be dissipated in time, it will cause thermal decay and performance degradation of the clutch plate. The 430 pull-type clutch assembly improves the heat dissipation performance of the clutch by optimizing the heat dissipation channel and increasing the heat dissipation area. This not only ensures stable operation of the clutch in high temperature environments, but also extends the service life of the clutch.

Precise adjustment mechanism: To ensure precise control of the clutch during engagement and disengagement, the 430 pull clutch assembly is equipped with a precise adjustment mechanism. Through the adjustment mechanism, the clutch pressing force and separation stroke can be accurately adjusted to ensure the best performance of the clutch under different working conditions. This design not only improves the smoothness of shifting, but also enhances the adaptability and reliability of the clutch.

The 430 pull clutch assembly has been widely used in the field of heavy trucks due to its unique structure and optimized design. Whether it is complex working conditions such as long-distance transportation, urban construction or mining, the 430 pull-type clutch can provide stable and reliable power transmission and smooth shifting.

In long-distance transportation, the 430 pull clutch can ensure the stability and comfort of the vehicle at high speeds. By optimizing the pressing force and separation stroke of the clutch, the shock and frustration during shifting can be reduced, and driving comfort and safety can be improved. At the same time, lightweight design and the application of wear-resistant materials can also reduce vehicle fuel consumption and emissions and improve transportation efficiency.

In urban construction, heavy trucks often need to drive on complex urban roads. The heavy-duty trucks 430 pull-type clutch ensures the vehicle's smoothness and reliability when driving at low speeds and frequently shifting gears by providing precise clutch control and stable power transmission. This not only improves construction efficiency but also reduces the impact of vehicles on urban traffic.

In mining, heavy-duty trucks are required to withstand extremely harsh working conditions and heavy loads. The 430 pull-type clutch can ensure stable operation of the clutch in high temperature and high load environments by optimizing heat dissipation design and improving wear resistance. At the same time, the precise adjustment mechanism can also achieve precise control of the clutch pressing force to adapt to the road conditions and load requirements of different mines.

English

English русский

русский

English

English  No.25, Hu Chuang Road, New District Industrial Park, Suzhou, Jiangsu, China.

No.25, Hu Chuang Road, New District Industrial Park, Suzhou, Jiangsu, China.  +86-13338663262

+86-13338663262