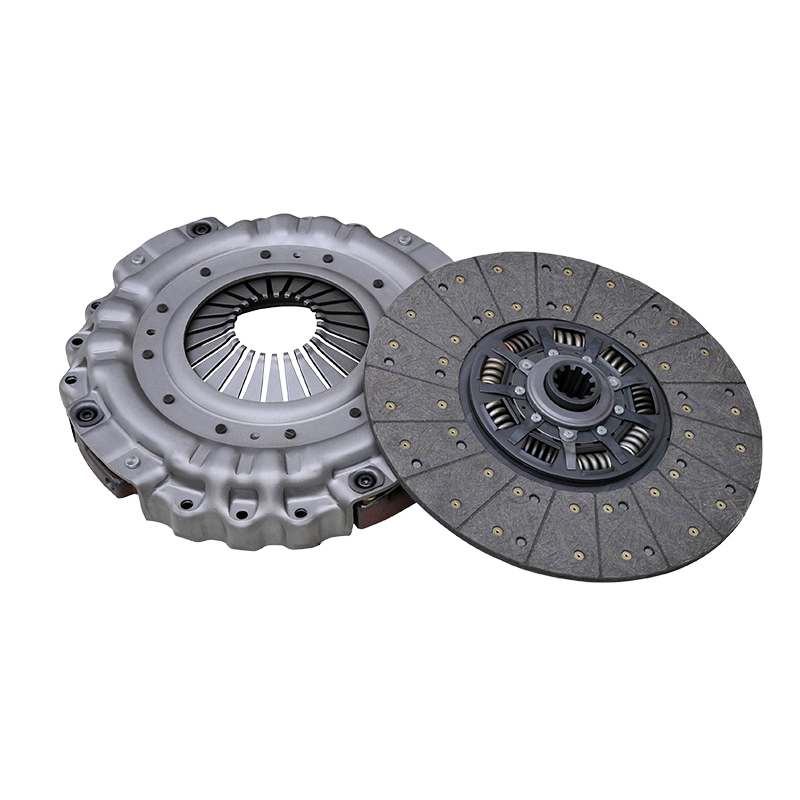

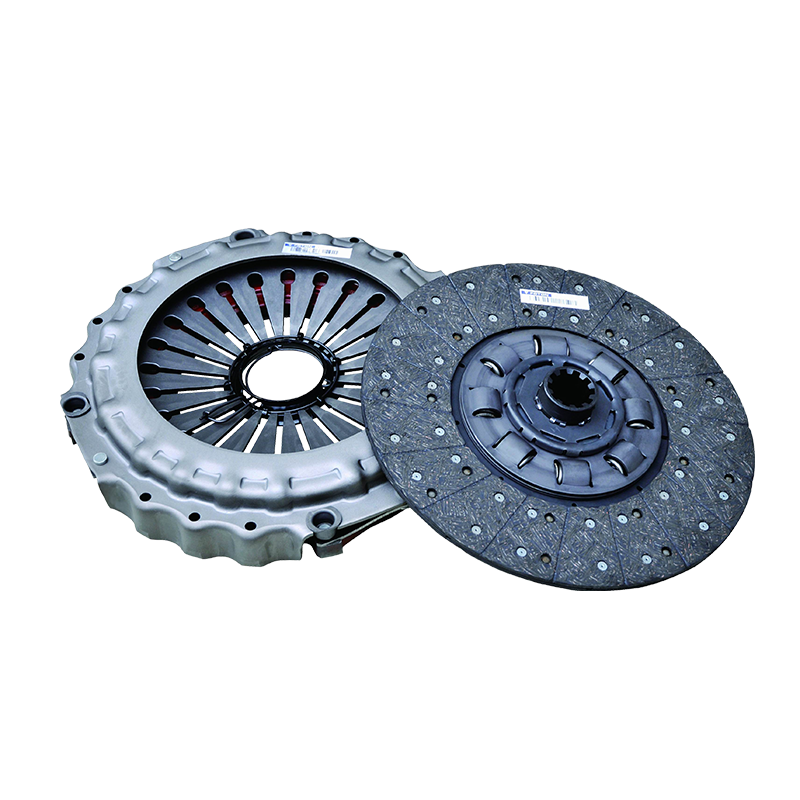

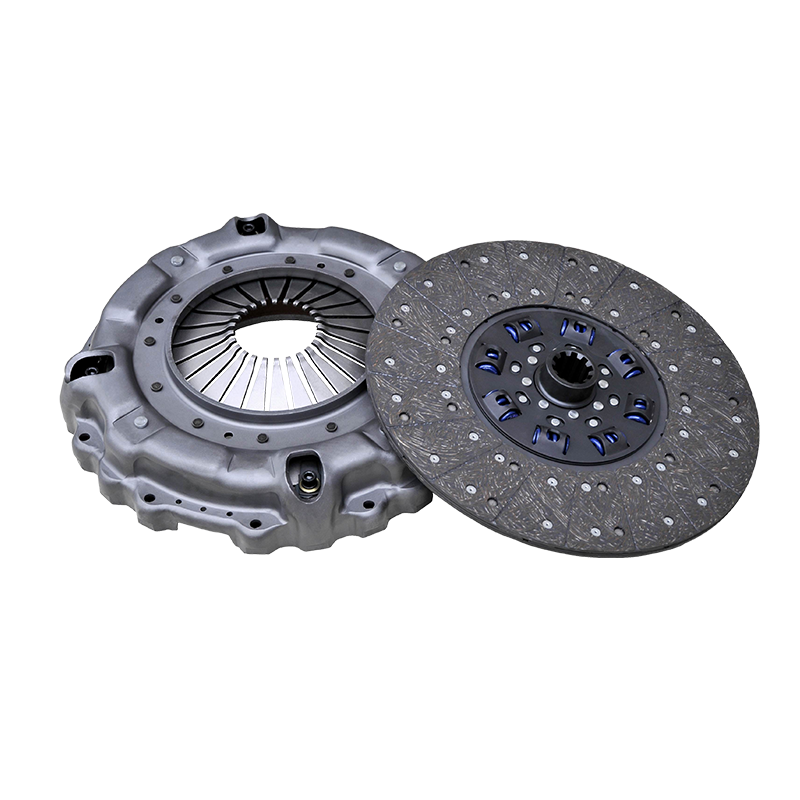

In the 420 clutch assembly, the active part is mainly composed of three components: flywheel, pressure plate and pressure plate spring. They each perform their duties and jointly complete the task of power transmission from the engine to the transmission.

Flywheel: the cornerstone of power storage and transmission

As the core component of the active part of the clutch, the flywheel is directly connected to the engine crankshaft and plays an important role in storing and transmitting engine energy. The design of the flywheel usually adopts heavy metal materials, such as cast iron or high-strength alloy, to provide sufficient rotational inertia to help the engine remain stable during operation. When the engine is working, the flywheel not only absorbs and stores part of the energy generated by the engine, but also provides continuous torque output between the up and down movement of the piston to ensure the continuity and stability of power transmission.

The surface of the flywheel is usually designed with specific teeth or grooves to facilitate meshing with components such as the starter and flywheel ring gear to start the engine. The flywheel is also the installation location of sensor components such as the engine speed sensor, providing key operating data for the vehicle's electronic control system.

Pressure plate: pressure control and maintenance of friction interface

The pressure plate, located below the flywheel, is fixed to the flywheel by a series of precise support structures (such as bolts, nuts and gaskets, etc.). The main function of the pressure plate is to provide the necessary pressure through the pressure plate spring below it when the clutch is engaged, so that the clutch plate fits tightly with the flywheel, thereby achieving effective transmission of engine torque.

The design of the pressure plate should not only consider the pressure and wear it bears, but also ensure its surface flatness to ensure uniform contact with the clutch plate. The pressure plate is usually also designed with ventilation holes to reduce the heat generated by friction and maintain the normal working temperature of the clutch.

Pressure plate spring: elastic adjustment and pressure stability

The pressure plate spring, located below the pressure plate, is an indispensable elastic element in the active part of the clutch. Their main function is to provide sufficient pressure when the clutch is engaged, so that the clutch plate is in close contact with the flywheel and transmits torque; when the clutch is disengaged, the elastic restoring force of the spring separates the pressure plate from the clutch plate and interrupts the power transmission.

The design of the pressure plate spring must take into account both rigidity and elasticity, ensuring that sufficient pressure can be provided when the clutch is engaged, and allowing it to quickly return to its original shape when the clutch is disengaged, reducing wear and energy loss. The number and layout of the pressure plate springs are also carefully calculated to ensure that the clutch can maintain stable pressure output under different working conditions and improve the efficiency and reliability of power transmission.

Precision collaboration and function realization of the active part

In the 420 clutch assembly, the flywheel, pressure plate and pressure plate spring of the active part realize power transmission from the engine to the transmission through precise collaboration. When the driver steps on the clutch pedal, the clutch release bearing pushes the pressure plate backward, compresses the pressure plate spring, reduces the pressure between the pressure plate and the clutch plate, and realizes the separation of the clutch. At this time, the power of the engine is no longer transmitted to the transmission through the clutch, and the vehicle is in neutral.

When the driver releases the clutch pedal, the pressure plate spring gradually returns to its original shape, pushing the pressure plate forward, increasing the pressure between the pressure plate and the clutch plate, and making the two fit tightly. The torque generated by the engine is transmitted to the transmission input shaft through the flywheel, pressure plate and clutch plate to realize power transmission. By precisely controlling the clutch engagement speed and pressure, the driver can smoothly adjust the output of the engine torque to achieve smooth starting and acceleration of the vehicle.

The importance of the active part in the automotive power transmission system

The precise design and efficient collaboration of the active part of the 420 clutch assembly not only ensure the continuity and stability of power transmission, but also improve the driving performance and safety of the vehicle. By precisely controlling the engagement and disengagement of the clutch, the driver can more flexibly control the driving state of the vehicle and achieve operations such as smooth starting, smooth shifting and emergency braking.

The design of the active part also takes into account the durability and maintenance cost of the vehicle. Key components such as the flywheel, pressure plate and pressure plate spring are made of high-strength and high-wear-resistant materials, and undergo strict manufacturing processes and quality control to ensure their reliability and durability during use. The standardized design of these components also facilitates maintenance and replacement, reducing the cost of using the vehicle.

English

English русский

русский

English

English  No.25, Hu Chuang Road, New District Industrial Park, Suzhou, Jiangsu, China.

No.25, Hu Chuang Road, New District Industrial Park, Suzhou, Jiangsu, China.  +86-13338663262

+86-13338663262