In the automotive industry, each component carries a specific function and mission, and they work together to ensure that the vehicle can travel safely and efficiently. Among the many key components, the clutch assembly is undoubtedly a shining pearl in the transmission system, especially when it comes to the 395 clutch assembly, its importance is self-evident. This clutch assembly occupies a pivotal position in the automotive manufacturing industry with its excellent performance, durable quality and wide range of applications.

As a bridge connecting the engine and the transmission, the clutch's main function is to achieve smooth transmission and interruption of power during the operation of the engine. When the driver steps on the clutch pedal, the friction plate inside the clutch separates from the flywheel, cutting off the power output of the engine to the transmission, allowing the vehicle to avoid setbacks when shifting or starting, ensuring smooth driving. When the clutch pedal is released, the friction plate and the flywheel are tightly combined, and the power is transmitted again, allowing the vehicle to continue moving forward.

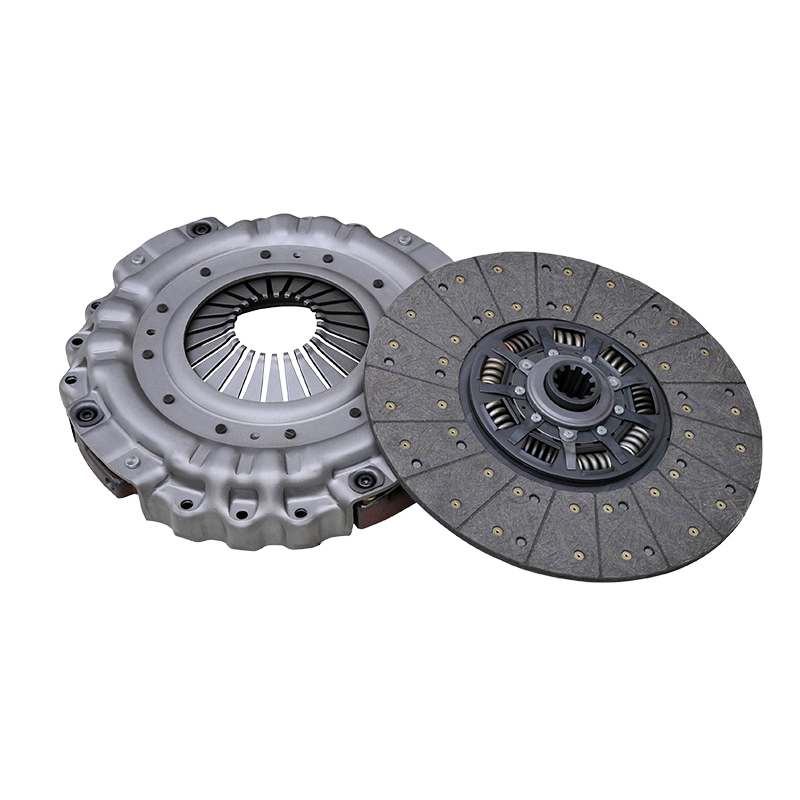

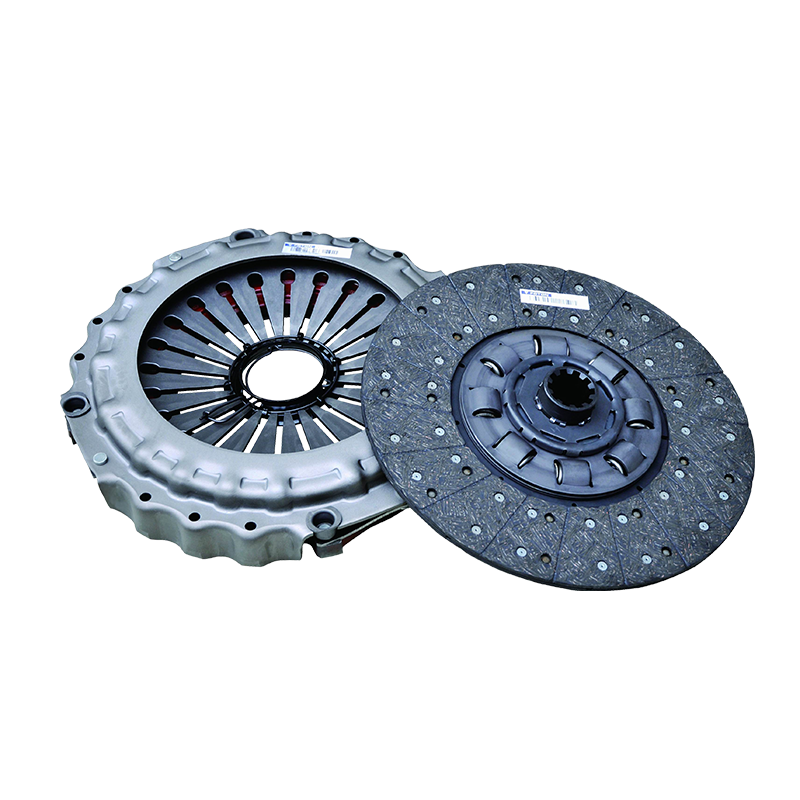

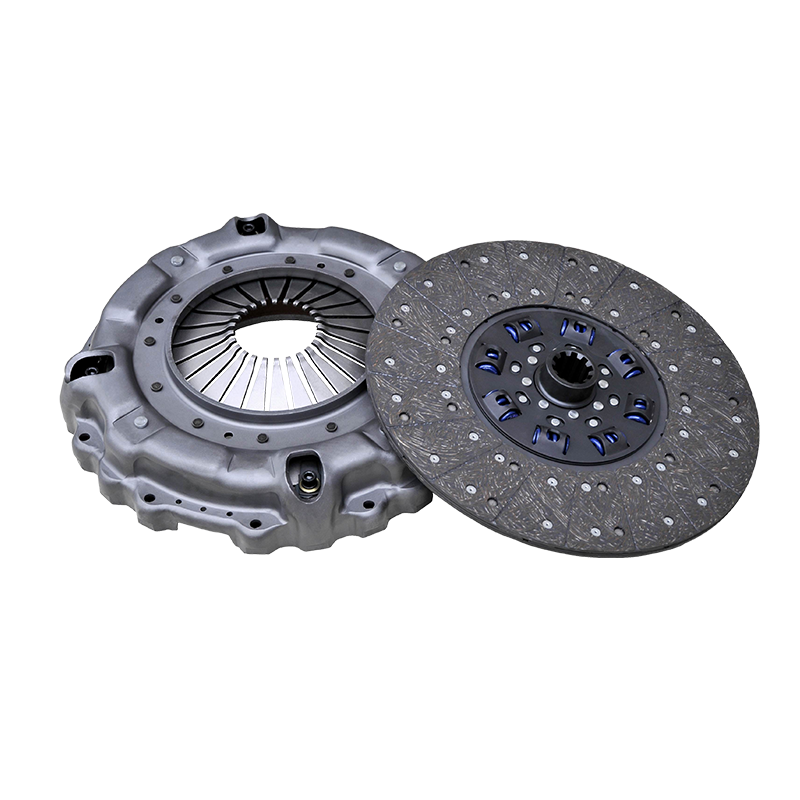

The design of the 395 clutch assembly fully takes into account the dual needs of modern cars for performance and durability. It uses high-strength, high-wear-resistant friction materials to ensure that it can maintain a stable friction coefficient and good wear resistance under long-term, high-load operation. The key components such as the pressure plate and release bearing inside the component have also undergone precision manufacturing and rigorous testing to ensure that it can always maintain the best working condition in complex and changing driving environments.

In addition to its outstanding performance, the 395 clutch assembly also shows great convenience in installation and maintenance. Its standardized design enables the clutch assembly to be seamlessly connected with a variety of models, greatly reducing the complexity and time cost of the installation process. The modular design inside the component allows only damaged parts to be replaced when repairing or replacing, without replacing the entire clutch assembly, thereby reducing maintenance costs and improving maintenance efficiency.

In actual applications, the performance of the 395 clutch assembly is also impressive. Whether it is frequent start-stop on urban roads or continuous acceleration on highways, it can provide drivers with clear and accurate clutch pedal feedback, ensuring that drivers can accurately judge the clutch engagement point and achieve smooth power transmission. At the same time, its excellent heat dissipation performance also enables the clutch to maintain stable friction performance under long-term high-load operation, avoiding power loss or clutch damage due to overheating.

English

English русский

русский

English

English  No.25, Hu Chuang Road, New District Industrial Park, Suzhou, Jiangsu, China.

No.25, Hu Chuang Road, New District Industrial Park, Suzhou, Jiangsu, China.  +86-13338663262

+86-13338663262